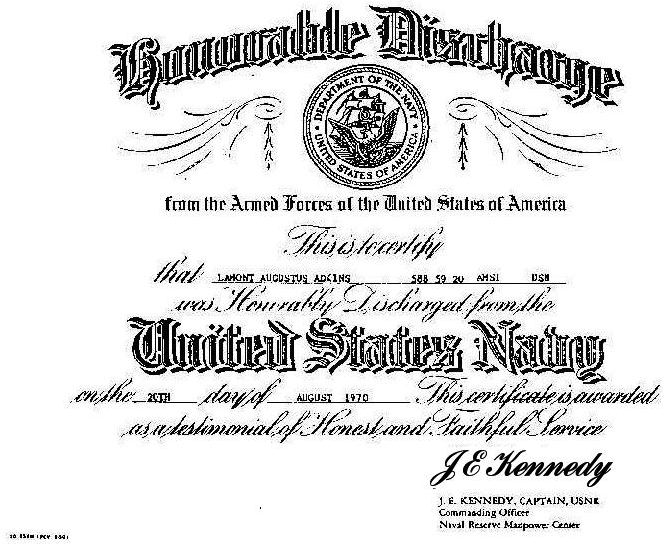

![]() 1957

1957 ![]() RETIRED

RETIRED ![]() 2005

2005 ![]()

A BASIC - ENTRY LEVEL - COMPREHENSIVE - INFORMATIONAL - RESOURCE site for:

the

Science

and

Art

of

WELDING

the

Science

and

Art

of

WELDING

![]()

![]() Standards

for Welding

Standards

for Welding  Resources

for Weldors

Resources

for Weldors

![]()

![]()

![]()

A

WELD

is a homogeneous

bond between two or more pieces of metal, wherein,

the strength

of the welded joint equals or exceeds the strength

of the original base metal *

*;

this is accomplished in part by controlling the

Welding

Process

Variables

and the elimination of welding

defects.

Base plate

- Face plate - Tacked - The weld - Weldment or Entry

Level Welder --- Advanced Level Welder --- Expert Level

Welder Today,

The

skill of

welding

*

is vital in the areas of Commerce,

National

Defense

From

its ancient roots until today, the science and art

of welding has served well both the artisan who

mastered the skill and the culture in which the

craftsman

practiced and applied this skills. Root -

Throat - Leg - Toe - Face Butt -

Corner - Edge - Lap - Tee WELD

TYPES Bead-

Fillet - Groove - Bevel - Plug - Spot FlatFlat

- Horizontal - Vertical - Overhead - 5G horiz. fixed - 6G

45 deg. Reference

line - Arrow - Symbol - Tail - Field weld - Weld all

around Aluminum -

Copper - Cast iron - Steel Sheet -

Pipe - Angle - Beam - Tube - Plate

"WELDING"

may be defined as: "A metal

- joining - process

by the use of heat

to cause coalescence

between two or more pieces of metal. It may be

performed with or without the use of a

filler

metal

and with or without the application of

pressure."

![]()

![]()

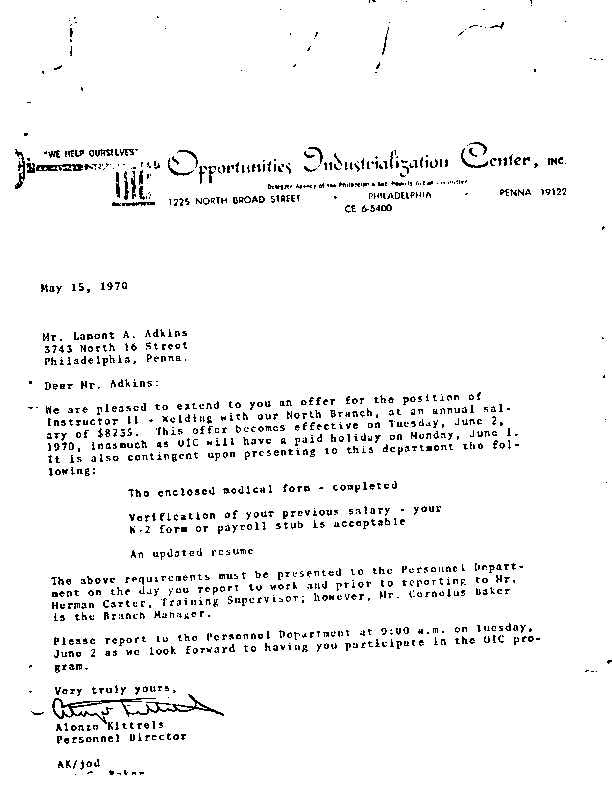

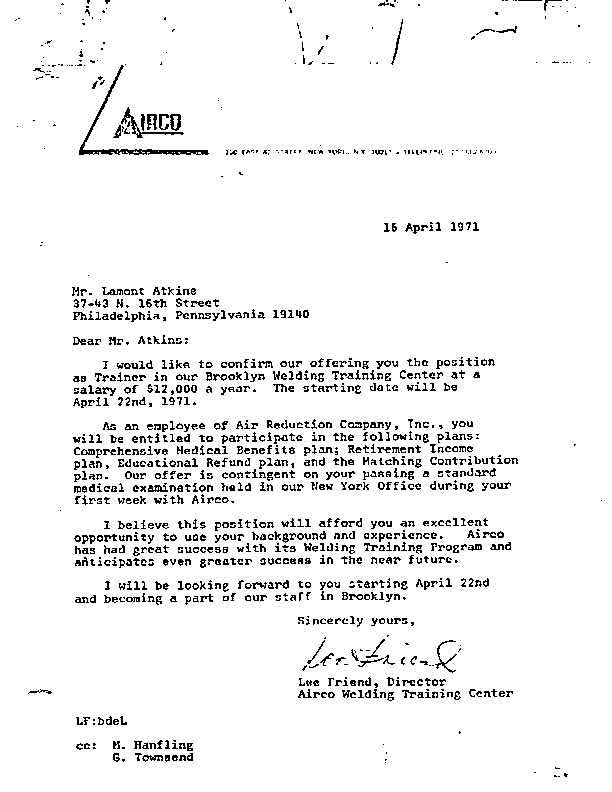

Welding

is a job

skill

used within many

trades

to manufacture, construct, produce, fabricate and /

or repair objects of metal. Welding is not a

trade! it

is a skill.

Basically, there are three levels:

These

can be attained by completing an

intensive

training

and certification

program.

![]() ,

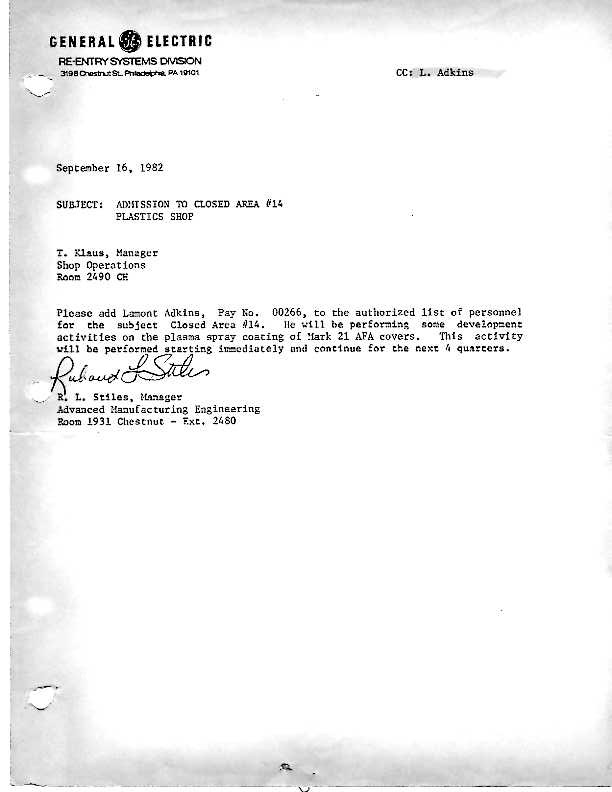

Aerospace

Video,

Shipbuilding,

Transportation,

Building

and Bridge

Construction,

Commercial Equipment, Industrial Apparatus and

Ornamental

Iron & Fabrication

Shops.

,

Aerospace

Video,

Shipbuilding,

Transportation,

Building

and Bridge

Construction,

Commercial Equipment, Industrial Apparatus and

Ornamental

Iron & Fabrication

Shops.![]()

![]()

The

skill of welding is very diverse and covers a wide

range of competency types and skill

levels

such as entry-level, apprentice, journeymen,

welding technician, certified welder, production

welder, fabricator,

welder

fitter,

pipe

fitter

/ steam

fitter,

welding

educator,

non-traditional,

{

see: DOT OOH

O*NET

}

![]()

![]()

![]()

![]()

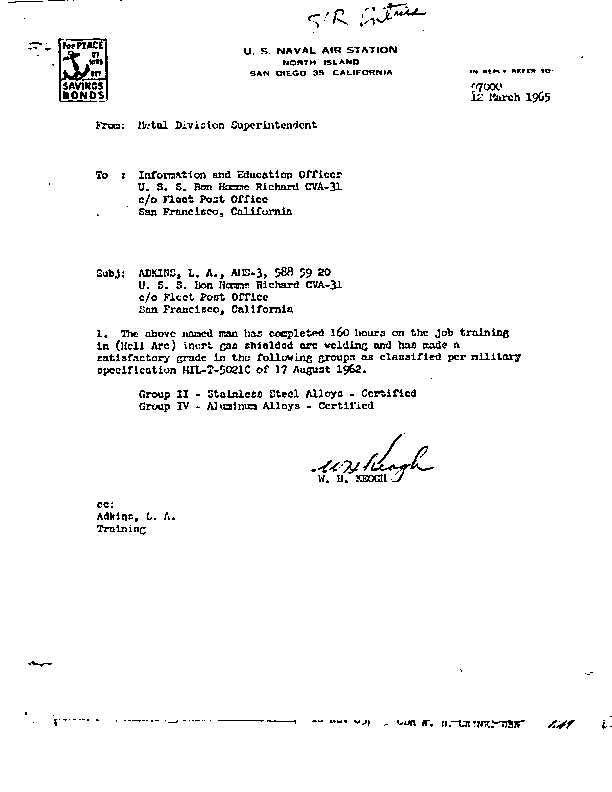

The

skill of welding is principally learned through

welder training and certification

programs run by

Vocational

Technical High

Schools

- Private

Trade Schools

- Community

Colleges

- Career & Technical Centers -

The

Military

- Company

Training

Programs

and Trade

Union or Apprenticeship Programs.

![]()

![]()

WELDING,

an Ancient Craft

(Gen.4:22).

Through

historical artifacts, the science and art of

welding can be traced back a very long way. The

tools, techniques the applications and methods have

changed tremendously, however, the purposeful

function has basically remained the

same.

![]()

![]()

It

is believed, by some, that welding was successfully

applied by the ancient metallurgist

to first craft

jewelry

and utensils. The applications was later extended

to become a major factor in the manufacture,

production and repair of tools and

weapons.

Today, welding is a critical force in our

Nations

defense

Video

A

and

commerce.

![]()

![]()

The

skill of welding, over the centuries, has evolved from

the basic forge welding process to encompass

over

80 different welding

processes

including plasma, electron-beam and state of the art

lasers. although the definitation and purpose for

welding has remained the same, the equipment, the

configuration, the methods, techniques and procedures

has changed tremendously. These welding processes

range from simple to complex. Even the application of

many of these welding process range from: Manual to

Semi-Automatic, Automatic, Automated, Computerized and

so on. However, the successful application of any

given welding operation depends mainly on the welding

operators understanding and command of the

PROCESS

VARIABLES.

![]()

![]()

![]() Standards

for Welding

Standards

for Welding  Resources

for Weldors

Resources

for Weldors

![]()

http:// ![]() OnLine

Welding Questions

OnLine

Welding Questions

![]()

![]()